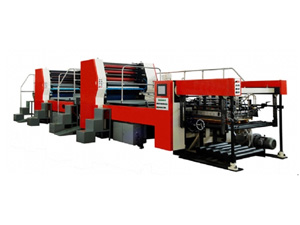

Printing & Packaging Machinery

Sheet Offset Printing Machine

Description:

The MP-450 sheet offset printing machine (double color offset printer) is widely used in iron-plate or PS plate printing. It can be connected to achieve single color, double colors and multi-color printing, and also can connect to coating and varnishing machine.

The process is that:

Materials are like that metal plates and PS printing plates, normally thickness of metal plate is that 0.15-0.4mm, and size of PS printing plate is that1160×1030×0.3mm.

Multiple same images are coated on a pre-processed metal sheet, and then the sheet is transferred to the s sheet offset printing machine (double color offset printer) one by one, and then each color is overprinted on each sheet.

Feature:

1. For the transmission system, the machine use none-shaft transmission synchronous device

2. There are step-less motors for both water fountain and ink duct rollers controlling separately, and the motors are synchronized to the main motor.

3. There are feeding device and main unit instant phase synchronized adjusted device for this machine.

4. The adoption of quick plate gripping device leads to decrease lead-time.

5. There is micro adjustment device for printing plate same direction.

6. For the ink route, it can be independently coming away.

7. The three main cylinders, we use high rigidity treated material for the surface, and there are pre-tightened bearing for the three main cylinders to insure quality printing

8. The sheet offset printing machine (double color offset printer) has pneumatic clutch.

9. There is also ethanol damping unit.

10. There are hard lining of cylinders to insure strong printing dots.

11. For the printing color, double color press can be operated separately.

12. There are fixed-point, fixed interval, fixed quality lubrication system for this machine..

13. There are also PLC controlled and fault display system, as well as man-machine inters phase intuitionist pictures.

Note: there are also other device for option, such as plate perforator for quick plate locating, electric driven sample reading machine, unit-static and dust eliminator device for mental plate, side blowers for printing aluminum plate, to name a few.

Why choose us? Main Specification of MP-450 Sheet Offset Printing Machine:| Max. size of metal plate | 1145×960mm |

| Min. size of metal plate | 710×510mm |

| Thickness of metal plate | 0.15-0.4mm |

| Max. printing size | 1135×945mm |

| Size of PS printing plate | 1160×1030×0.3mm |

| Size of rubber blanket | 1175×1130×1.9mm |

| Blank side width | 6mm |

| Max. speed | 6000s/h |

| Max. printing speed | 5000s/h |

| Max. feeding weight | 2500kg |

| Power of main motor | 15Kw per printing unit |

| Capacity of air pump | 140m³/h |

| Dimensions (L×W×H) Double colors | 13000×3200×2280mm |

| Dimensions (L×W×H) Single color | 8300×3200×2280mm |

Founded in 2009, Lantytk® Corp has continually focused on providing a wide variety of paper cutter printing machine, flexographic printer for customers around the world. We are very familiar with international market of rigid box maker (rigid box production line), woven bag production line (fabric bag making machine), and its trend of development. With products of high quality assurance and CE certificated, we are sure to provide our customers with the best products at competitive price.

- Central Impression Flexographic PressThis GF central impression flexographic press (flexo CI printing machine) is a kind of printing line for flexo products, such as BOPP film (18-45um), CPP (18-60um), PET (12-30um), PVC (25-75um), PE (30-100um), paper (30-120GSM), etc. This machine equipped with CI drum, is suitable for the printing color of four-color, six-color, eight-color and ten-color, with the Max printing ...

- Automatic Flexo Printer Slotter and Flexo Die CutterOur flexo printer slotter and flexo die cutter is a kind of cardboard printing line consisting front edge feeding, printing, slotting, die cutting. The feeding machine is intermittent, with the rear-kicking function. During the slotting process, the cardboard creasing process can also be finished. Thin cardboard and curving cardboard are available for this machine...