Printing & Packaging Machinery

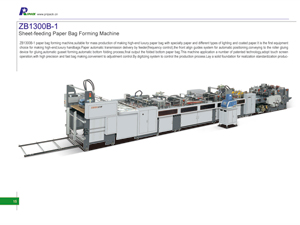

ZB1300B-1 Sheet-feeding Paper Bag Making Machine

Description:

ZB1300B-1 sheet fed paper bag making machine is among the top choices for manufacturers to mass produce paper bags, especially top grade luxurious handbags from special paper and different types of laminating and coating paper. This bag making machine adopts touchscreen operation, which makes it possible for the machine to run at high speed and precision, and conveniently adjusted. This paper bag making machine employs several patented techniques and its up-to-standard operation procedure and advanced data management solutions will guarantee you a stable and speedy bag making process.

Constituent Parts and Their Features

Enhanced Pre-Stack Paper Feeder: non-stop paper feeding, shortening the loading and adjusting time of raw paper.

Front and Side Guides: accurate position of every sheet by the align guides, guaranteeing the uniformity of every batch.

Gluing system

It adopts both hot-melt and water-soluble cold glue for pasting, between which two the hot-melt glue device can be used independently and water-soluble cold glue with tape roll adhesive gluing system.

Screw Rod Adjusting Device

The screw rod adjustment system installed on this bag making machine shortens the adjusting time and improves the production efficiency in making handbags of different specification.

Gluing System (water-soluble cold glue )

water-soluble cold glue (with tape roll adhesive gluing system)

Gluing System (hot-melt glue)

hot-melt (with spray gun adhesive gluing system).

Automatic Collecting System

It is capable of setting the amount for each package and capable of automatic counting, inserting marker, which makes it simple for mass production, reduces lasbor costs, and improves working efficiency.

Operation Procedure:

Auto Paper Feeding—Gluing—Tube Forming—Pasting—Tube Compressing —Tubing—Bottom Folding

Applicable Paper:

Applicable paper for this sheet fed paper bag making machine includes the following types: kraft paper, art paper, white board paper, white cardboard (including film-laminating paper).

| A | B | C | D | E | |

| Max. Size | 1200mm | 650 mm | 180 mm | 450 mm | 530 mm |

| Min. Size | 700 mm | 360 mm | 80 mm | 250 mm | 250 mm |

| Max. sheet(LXW) | 1200×650mm |

| Min. sheet(LXW) | 700×360mm |

| Sheet Weight | 100-300gsm |

| Bottom Width | 80-180mm |

| Bag Width | 250-450mm |

| Bag Length | 250-530mm |

| Total Power | 14kw |

| Machine Size | 14300×2400×1800mm |

| Speed | 60-90pcs/min |

| Total Weight | 12T |

| Glue Type | Water Soluble Cold Glue(hot-melt glue) |

- Aluminum Lid Punching Embossing MachineThis SPB-400 aluminum lid punching and embossing machine is mainly used to convert printed or unprinted aluminum foil into little sheets. It can also convert plastic foil and paper. Yogurt lids, labels packing in food and beverage industry always use this machine. This machine can finish embossing, lid punching, lids collecting and lid counting together with high efficiency...

- Paper Bag Making MachineThis ZB960C sheet feed paper bag making machine (paper bag production line) is a kind of newly developed automatic paper bag maker for various types of paper bags. The processing flow is that, sheet feeding, gluing, side pasting, tube forming, tube, bottom folding, gluing, bottom pasting, and bag out. This pre-load feeder can lead to non-stop operation. There is PLC controller ...