Printing & Packaging Machinery

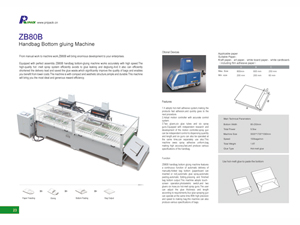

ZB80B Handbag Bottom Gluing Machine

Description:

ZB80B handbag bottom gluing machine boasts compact and aesthetic structure, simple operation and durable service life time and featured of even gluing, accurate folding and high speed, which will undoubtedly improves bag’s quality and productivity significantly and thus makes manufacturers to own customers’ recognition and benefit more from lower costs. Its holt-melt spray system of high quality efficiently avoids glue leaking and misses. This handbag bottom gluing machine enables manufacturers to get rid of traditional manual work and will bring enormous development to their enterprises through machine work.

Function:

ZB80B handbag bottom gluing machine runs in the following working procedures: manual feeding, auto conveying and gluing, auto bottom sealing and compressing, and finished bag outputting and so forth. Among the two gluing systems, six glue hoses and six spray guns equipped, glue guns can be independently controlled when it comes to the amount and tape length of glue, meanwhile, six guns can also be operated simultaneously. This gluing machine makes bags’ size accurate and glue spraying well-distributed.

Operation Procedure

Tube Feeding—Gluing—Bottom Pasting—Bag Outputting

Features

1. By employing holt-melt adhesive system, ZB80B handbag bottom gluing machine renders the bag bottom quickly pasted, and able to be sent to the next procedure as soon as possible.

2. The gluing machine adopts motion controller which enjoys accurate control system respectively on the two hot-melt adhesive systems, six glue tubes and six spray guns and the units. Therefore, glue guns can be independently controlled for glue amount and tape length, and six guns can be used simultaneously.

3. ZB80B handbag bottom gluing machine sprays glue evenly, achieves high accuracy and speedy production, and can produce handbags of various specifications.

Kraft paper, art paper, white board paper, and white cardboard (including film laminating paper) are the applicable paper on this gluing machine.

| A | B | C | |

| Max. Size | 800mm | 600 mm | 250 mm |

| Min. Size | 200 mm | 200 mm | 60 mm |

| Bottom Width | 60-250mm |

| Total Power | 9.5kw |

| Machine Size | 5005×1705×1590mm |

| Speed | 100bags/min |

| Total Weight | 1.8T |

| Glue Type | Hot-melt Glue |

Related Products

- Label Flexographic Printer The ZBS-320/320G label flexographic printer is a kind of flexo logo printing machine with three die-cutting stations.The equipment can finish the whole process of material-feeding, printing, varnishing, drying, laminating, die-cutting, and rewinding and sheeting in a lump. It is an idea note flexo printing machine and top-grade adhesive label flexo printing machinery with 5 color print ability...

- Automatic Multi Color Label Screen PrinterThis XH-300 automatic multi color label screen printer is a kind of label screen printing machine for printing soft tape materials. This machine is mechanism, electricity and pneumatics integrated, leading to the finished label products in ink density, good fastness, high ink coverage and precise registration. This printing machine is especially suitable for printing on materials with ...