Printing & Packaging Machinery

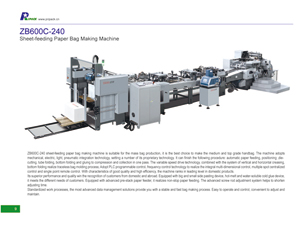

ZB600C-240 Sheet-feeding Paper Bag Making Machine

Description:

ZB600C-240 sheet-feeding paper bag making machine is an excellent choice for manufacturers to mass produce mid-range and top grade handbags of high quality. Meanwhile, it has been recognized by customers at home and abroad due to its superior performance and quality. Its up-to-standard operation procedure and advanced data management solutions makes the bag making process stable and speedy.

Features:

1. This sheet-feeding paper bag making machine integrates technologies from mechanics, electrics, lighting, pneumatics and finishes all at once automatically paper feeding, positioning, creasing, tube folding, bottom folding, gluing, compressing, and collecting.

2. By the adoption of PLC programmable control and frequency control technology, the machine achieves integral multi-dimensional controlling, multiple spot centralized controlling, and single point remote controlling.

3. ZB600C-240 sheet-feeding paper bag making machine can produce traceless bags because it employs variable speed drive technology and vertical and horizontal creasing system.

4. It is operated and controlled easily, adjusted and maintained conveniently, and thus is efficient, ranking in leading position in domestic market.

5. This sheet-feeding paper bag making machine satisfies different needs of customers due to its equipment of big and small side pasting device, as well as hot-melt and water-soluble cold glue device.

6. It conducts non-stop paper feeding due to its employment of advanced pre-stack paper feeder.

7. The sheet fed paper bag making machine significantly shortens adjusting time due to its advanced screw rod adjustment system.

Operation Procedure

Sheet Feeding —Gluing —Tube Forming—Side Pasting—Compressing

Outputting—Tubing—Bottom Folding—Gluing—Bottom Pasting—Finished Bag Outputting

Kraft paper, art paper, white board paper, and white cardboard (including film-laminated paper) are all applicable on this sheet fed paper bag making machine.

| A | B | C | D | E | |

| Max. Size | 600mm | 410mm | 100mm | 240mm | 320mm |

| Min. size | 325mm | 210mm | 50mm | 100mm | 120mm |

| Max. Sheet(LXW) | 600×410mm |

| Min. Sheet(LXW) | 325×210mm |

| Sheet Weight | 80-190gsm |

| Bag Width | 100-240mm |

| Bottom Width | 50-100mm |

| Bag Length | 120-320mm |

| Total Power | 9kw |

| Machine Size | 13000×1850×1850mm |

| Speed | 70-100pcs/min |

| Total Weight | 9T |

| Glue Type | Water Soluble Cold Glue(hot-melt glue) |

- Aluminum Lid Punching Embossing MachineThis SPB-400 aluminum lid punching and embossing machine is mainly used to convert printed or unprinted aluminum foil into little sheets. It can also convert plastic foil and paper. Yogurt lids, labels packing in food and beverage industry always use this machine. This machine can finish embossing, lid punching, lids collecting and lid counting together with high efficiency...

- Paper Bag Making MachineThis ZB960C sheet feed paper bag making machine (paper bag production line) is a kind of newly developed automatic paper bag maker for various types of paper bags. The processing flow is that, sheet feeding, gluing, side pasting, tube forming, tube, bottom folding, gluing, bottom pasting, and bag out. This pre-load feeder can lead to non-stop operation. There is PLC controller ...